Electronic devices used across industries are becoming increasingly complex in terms of features, designs, and functionalities, and all of this functions based on the printed circuit board assembly (PCBA). A PCB assembly is an integral part of almost all electronic and electromechanical devices. Nowadays, most PCBAs comprise several components and complex designs as they need to cater to the complex features of devices. Hence, most times, automation is used to mount these components on the blank boards, for soldering, testing & inspection, and various aspects of PCB manufacturing and assembling. So, the PCB assembly equipment involves a lot of hardware such as machines for picking and placing components, soldering, testing, and more. This post discusses the PCB assembly process and various equipment required at each stage.

PCB Assembly Process Discussed in Brief

PCB manufacturing and assembling are two different processes, and hence the machines and tools required for each of these processes are different as well. PCB manufacturing comprises making blank boards, while assembling involves component mounting, circuit formation, and more. The PCB assembly process comprises the following steps.

-

Once the blank boards are manufactured, the components are mounted through surface mounting. If it is single sided surface mount, solder paste is used and SMDs are mounted with a pick and place tool. Then reflow soldering is performed. If the SMD is double sided, an SMT adhesive is applied, and hand soldering is done. After this, testing is performed to check the structure and functions of PCBA.

-

In case of single sided SMDs, x-ray inspection is performed after reflow soldering as there is no need of adhesive. Thru-hole mounting is used to place the components after which hand soldering is done if required. This PCBA is now ready for testing and inspection.

How PCB Assembly Equipment Helps Assemble PCBs?

The components on PCB assemblies may be mounted either manually or through machines. While manual mounting is not very common now, it requires a different set of tools. Using machines for mounting components, soldering, and so on has gained traction over the last few years. This is mainly because the board sizes have reduced and their design is complex.

Here are some types of manual

PCB assembly equipment.

-

Screwdrivers

-

Pliers and cutters

-

Solder paste

-

Wires

-

SMD blower

-

Soldering machine

-

Magnifiers and microscopes

Here are some tools and equipment used in automated PCB assembly.

-

Pick and place machines

-

Reflow and wave soldering machines for thru-hole technology

-

Solder paste and glue dispensing machine

-

Machines for testing- in-circuit and AOI

-

Functional validation testing (FVT)

Get Introduced to Equipment Used in Each Stage of PCB Assembly

Get Introduced to Equipment Used in Each Stage of PCB Assembly

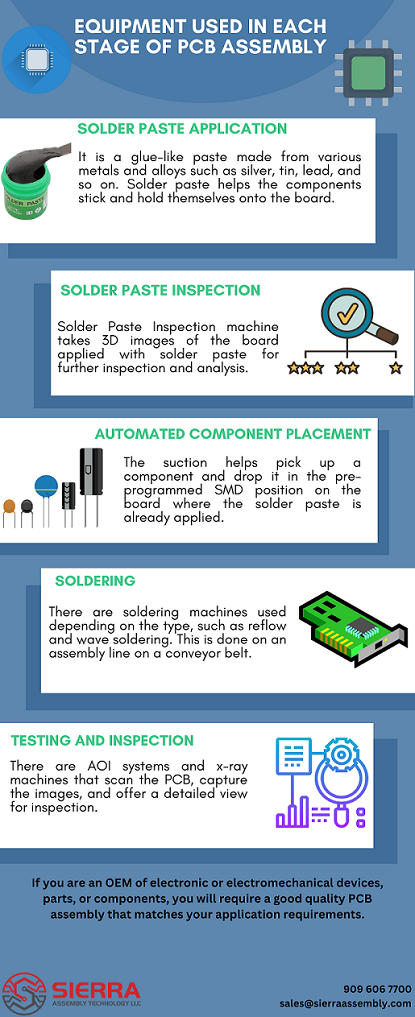

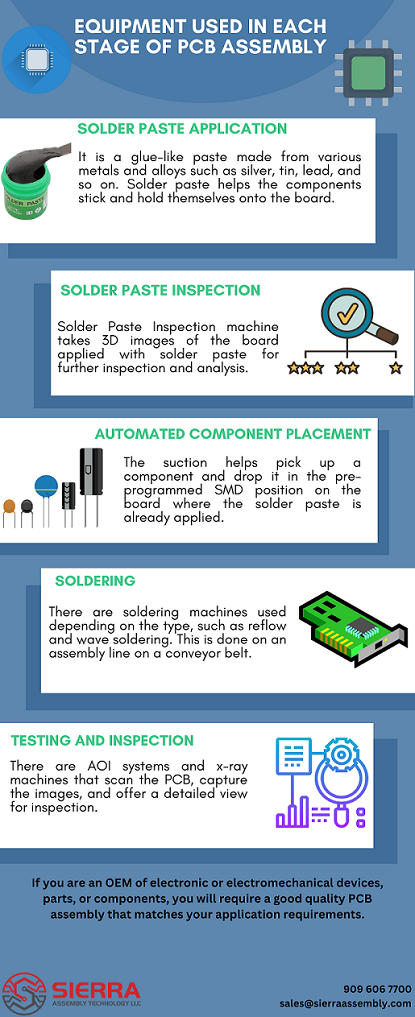

In case of automated PCB assembly, different equipment is used in each stage of assembly. Surface mount technology is widely used in component mounting and assembly. These are the steps in PCB assembly using surface mounting technology.

-

Solder paste application: Here, solder paste is applied onto the board. This is a glue-like paste made from various metals and alloys such as silver, tin, lead, and so on. This helps the components stick and hold themselves onto the board. In case of RoHS compliant boards, a lead-free paste is applied. It is applied only onto SMD pads where the components would be mounted. An automatic printer is used to apply this paste wherein the PCB stencil and the boards are locked in. The amount of the paste is set and a blade is used to deposit the right amounts across the PCB stencil in specified portions. Once the PCB stencil is removed, the paste easily moves in the required SMD areas.

-

Solder paste inspection: There is a machine which inspects the solder paste that is applied onto the board, which helps eliminate soldering issues. This is especially useful in high-volume PCBAs. This SPI machine takes 3D images of the board applied with solder paste for further inspection and analysis. This helps rectify solder alignment, height, and volume. This testing technique is often used together with automated optical inspection (AOI).

-

Automated component placement: In wave as well as reflow soldering, minute dots of glue are applied on the portions where the components are to be placed. This is done with the help of glue dispensing machine. The next step is the actual component placement, and there is a pick-n-place machine to do this task accurately. The suction helps pick up a component and drop it in the pre-programmed SMD position on the board where the solder paste is already applied. This whole process happens pretty fast.

-

Soldering: There are soldering machines used depending on the type, such as reflow and wave soldering. This is done on an assembly line on a conveyor belt. Once the board has all its components in place, it is exposed to set temperatures in a controlled environment, where the solder paste melts due to heat and hardens again. This helps establish electrical connectivity between the SMD pads and the components. The controlled temperature environments on the assembly line help in drying the solder paste, followed by preheating, melting, wetting, and cooling. This completes the soldering process.

-

Reflow soldering: This is commonly used for ball grid arrays (BGAs), QFN, and so on. It uses a reflow oven with convection and conduction heating types with uniform temperature. This soldering temperature can be set for other batches of PCBA as well.

-

Wave soldering: Here, a layer of flux is applied to SMD pads and components and the boards are preheated. They are then passed through a wave of molten solder. This technique is used to assemble thru-hole components.

-

Testing and Inspection: This is a crucial stage of PCB assembly and various techniques such as visual inspection, AOI, in-circuit testing, and more are used to check the quality, accuracy and functionality of PCBAs. Testing can be performed at each or any of the stages. There are AOI systems and x-ray machines that scan the board, capture the images, and offer a detailed view for inspection. These images are then compared to reference boards to identify any errors such as missing components, open wires, shorts, and scratches.

If you are an OEM of electronic or electromechanical devices, parts, or components, you will require a good quality PCB assembly that matches your application requirements. Hence, it is essential to partner with an experienced

PCB assembly service provider who has the right experience as well as advanced PCB assembly equipment, and who can understand your requirements and deliver accordingly. It is wise to look for a PCBA services provider who can answer all your relevant questions and is transparent in terms of the materials as well as PCB assembly equipment they use. Sierra Assembly is a US-based manufacturer of PCBAs offering customized and end-to-end PCB solutions. The company offers end-to-end services and various types of PCB assemblies such as quick turn, mixed technology, and so on.