Subscribe to get the latest news and updates. No span, we promise.

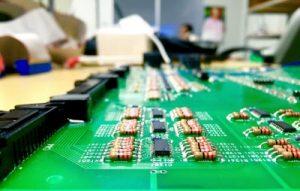

A poor layout and design may lead to several performance issues when it comes to the assembly of high-speed PCBs. The following are the areas you must pay close attention to while working on a high-speed PCB assembly project.

Planning: High-speed PCB assembly requires enough planning pertaining to signal speed, sensitive signals, material requirements, and other customer specific requirements. Note down all the points to avoid confusions in the later stage.

Prepare Schematic Diagrams: Pay great attention while preparing schematic as it helps throughout the high-speed PCB assembly. With an accurate depiction of the circuitry flow in the schematic, engineers who are assigned to work on the board get a clear idea of the ordering of components, routing of differential pairs, clock lines, among others. This in turn helps them to decide on the layout of the high-speed PCBs. On the whole, preparing schematic is the first stage, which tremendously helps in organizing and presenting high-speed design.

Collaboration: In most cases, the person working on the schematic may not be the same who is deployed to assemble the board. Hence, it is advisable for the personnel who takes charge later to have a discussion with the one who has done the initial schematic and layout.

Board Materials and Stack up Requirements: The materials used in the assembly have a huge role to play in determining the speed of the final assembly. Compared to standard PCBs, specialized materials are being utilized in the production of high-speed boards. A few amongst the materials used include FR-4 and Rogers. Meanwhile, how the layer stack-up is structured also holds great significance in determining the speed of the final assembly. Placing a signal layer adjacent to a plane layer, routing high-speed signals on the inner layers between planes, and using of multiple ground planes in layer stack up help optimize the speed.

Component Placement: There are some tried and tested component placement strategies specific to high-speed PCBs. You can place the components in critical power locations or arrange input/output points or individual circuits in a way to enhance the circuitry speed.

Power and Ground Planes: It is recommended to avoid splitting the ground plane with any routed signals. Doing so results in nasty EMI and signal timing issues, which in turn affects the PCB speed.

Land Patterns Size: Designing larger pads is common for standard boards but not advisable for high-speed circuitry. It is always better to maintain the size of pads at 0-5% of the size of the component pins. This in-turn gives more space to assemble differential pairs, vias, and FPGAs or ICs, which is necessary to optimize the board’s speed.

Parasitics: These are basically unintended stray capacitance, which affect the performance and speed of the final assembly. So, it is important to find out the source of such Parasitics and avoid such inductance in high-speed board design.

Routing/shielding: Interference of signals on boards with one another is a common problem the designers face. Be aware that such signal conflicts between signal paths cannot be allowed when designing high-speed PCBs. Maintaining a good distance between signal traces, minimizing long traces on adjacent board layers and maintaining minimum long parallel runs will help to tackle the issue.